+86-769-81360038

Dongguan linghang Hardware Products Factory is located in Chikan Industrial Zone, Shipai Town, Dongguan City, Guangdong Province. It is a one-stop manufacturer of hardware machinery and moulds to produce hardware jewelry chains and hardware accessories. The factory is a Dongguan hardware products processing plant, hardware machinery factory, hardware jewelry parts factory, metal jewelry chain manufacturers.

In 2010, the smog of the international financial crisis still shrouded the global hardware industry, but the Chinese hardware market was the first to pick up, and the industry showed a recovery growth. According to customs statistics, in 2010, the total import and export volume of the whole industry reached 74.923 billion US dollars. The year-on-year increase was 30.1%, of which the total export value was US.51 billion, a year-on-year increase of 31.4%; the total import value was US.412 billion, a year-on-year increase of 26%. According to the National Bureau of Statistics, from January to October 2010, sales of the whole industry increased by 27% over the same period of the previous year.

China Net: Why does China's hardware industry achieve such rapid growth? What kind of development strategy and development focus will the hardware industry have during the “Twelfth Five-Year Plan” period? The author interviewed Shi Lanlan, executive vice president of China Hardware Products Association.

The shrinking international market demand has caused a heavy blow to the global hardware industry. How can China's hardware industry achieve sustained growth?

Shi Jielan: In the downturn of development, China Hardware Products Association guided the adjustment strategy of the whole industry, accelerated transformation and structural adjustment, and shifted from export-oriented to two legs of “both domestic trade and foreign trade, both domestic and foreign markets”. Walk and continue to explore the domestic market. This kind of positive driving effect has achieved remarkable results, which triggered a comprehensive rebound in the hardware industry, especially in the domestic sales, showing an explosive growth, achieving a high growth rate of 27% in the whole industry.

China Net: On the basis of the rapid growth of the “Eleventh Five-Year Plan”, what major changes in the hardware products industry will be during the “Twelfth Five-Year Plan” period?

Shijielan: The 12th Five-Year Plan has higher requirements. The state has proposed that the industry should be transformed into a low-carbon environment, but how to change it specifically requires the industry and enterprises to make in-depth thinking and deep-seated changes in light of their own conditions.

Transformation is not a change, not from the current production area to other production areas. In fact, the core of industrial transformation is upgrading, moving from the current situation to a higher-level industrial model. Recently, in accordance with the direction of the “Twelfth Five-Year Plan” and the requirements of the national industrial policy, the China Hardware Products Association has refined the five major changes implemented during the “Twelfth Five-Year Plan” period. This is the planning and upgrading of the hardware industry in the next five years. The main direction and focus of work.

China Net: It is reported that the association put forward the requirement of “intensive cultivation” at the beginning of the year. Is this the connotation of transformation and development? What is the content of the “five major changes”?

Ishigaki: The first change is: the transition from extensive to intensive. Change the original industry small, multi, weak, scattered status, improve product processing capabilities, enhance manufacturing equipment, technology, create brands, and take an intensive development path.

In the development process of the past 15 years, the hardware industry has basically followed the road of extensive development. High-pollution, low-level, repetitive labor, low-end products and shortage of high-end products have always existed, which not only caused resources. The waste, the destruction of the environment, also restricts its own development. Today, this growth model has come to an end.

The core of extensive transformation to intensive transformation is to improve product processing capability and quality level, and take the road of independent innovation and independent brand development. Improving quality, creating their own brands, channels, and independent innovation capabilities have become a top priority, and the transition from extensive to intensive is imminent.

The second shift is: from labor-intensive to technology-intensive. Labor-intensive industries can also introduce modern electronics, IT and other technologies into the industry.

The faucet industrial design competition announced at the China International Hardware Show 2010 is the demonstration and guidance of the industry from the industrial design to increase the technical content and added value of the products. The hardware industry has a wide variety of products, each with its own characteristics, and it is a technology-intensive road with a lot of room for growth.

China Net: How much space does it take to develop in a high-end market with a technology-intensive road?

Shijielan: The space is very large, but most of the high-end market is currently occupied by overseas brands. For example, the import value of construction hardware last year was 4.99 billion US dollars, an increase of nearly 30%. In other words, the market equivalent to more than 30 billion yuan has been obtained by foreign brands. This aspect shows that domestic consumers not only have demand for high-end products, but also increase year by year. On the other hand, it also shows that domestic brands are not enough to meet the needs of this part of the market, and the quality improvement needs to be realized.

Therefore, the third shift in the industry is the shift from quantitative expansion to qualitative improvement. At present, the status quo of product homogenization and low-level repetitive labor in the industry has not been improved. To achieve the transition from a large producing country to a strong producing country, we must overcome the current situation of excessive low-end products and insufficient high-end products.

The fourth change is: low cost, low price to high value added, high profit margin. The low-price competition between peers is an act that harms the industry and loses both sides. The positive example is the range hood industry. Until now, there has been no price war. The tradition of this industry has always been to compete in technology, starting from the connotation and added value of the product itself to gain market favor and maintain the orderly and healthy industry. Ecological environment.

China Net: Brand strategy should be the way out for competition. In this regard, how is the association guided?

Shijielan: We emphasize that the hardware industry should give full play to its own advantages, increase brand connotation, do brand promotion, create and promote the establishment of sales channels. At present, the domestic market is very mature, so it is rooted in the domestic market, especially high-end. The market can grasp the initiative and is not afraid of the impact of the international financial crisis.

The fifth change in the industry is: export-oriented OEM-based to independent brands. Paying attention to the domestic market is not abandoning the international market. Walking on two legs means that both domestic and foreign markets are equal and parallel. OEMs are always taking orders, production and delivery at three points and one line. They know nothing about the domestic market, standards and trends. This kind of industry model that is completely dependent on each other is very dangerous. Once the customer changes, the company is very likely. Into a comprehensive crisis. Therefore, we must master the autonomy of the brand and walk out of a solid independent brand.

The above "five major changes" is the focus of the "12th Five-Year" China hardware industry. To achieve the transformation from “manufacturing power to manufacturing power”, we must take a solid footstep towards this goal.

Dongguan linghang Hardware Products Factory

Address: Building 69, Tangwei Commercial District, Shipai Town, Dongguan City, Guangdong Province

Telephone: +86-769-81360038/+86-769-81819982

Contact: +86-13612693831/+86-18926832163 (Mr. Huang)

+86-13662760633/+86-18925793217 (Miss Li)

Company homepage: en.dglinghang.cn

Email: linghang@dglinghang.cn

linghang91@163.com

QQ: 1157797072

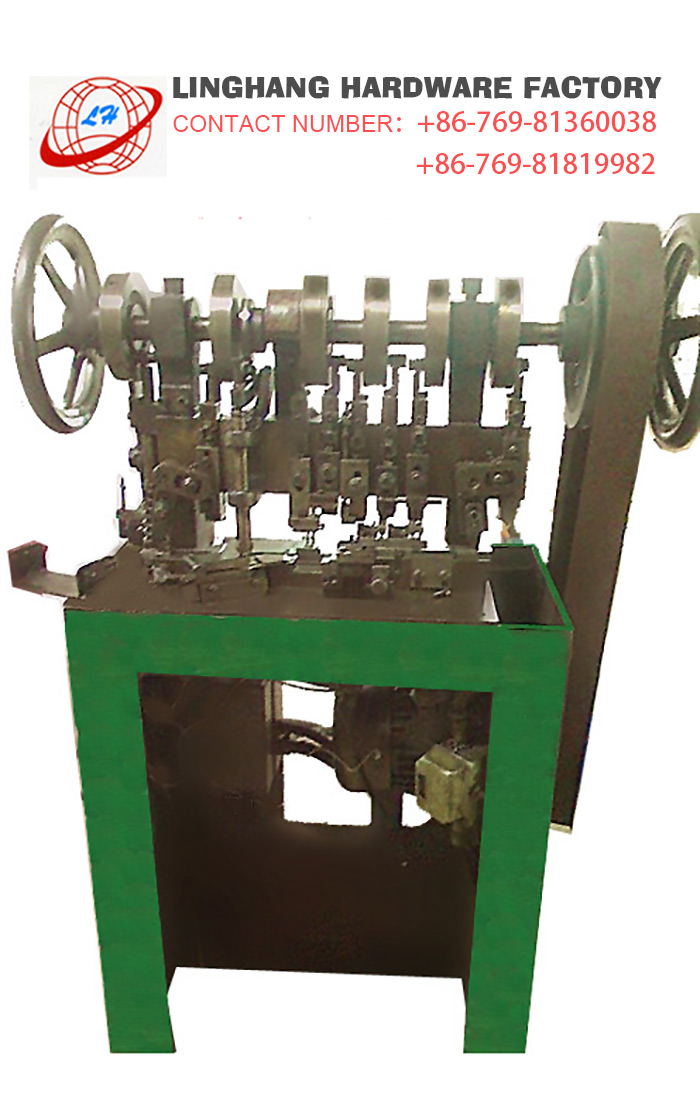

Dongguan linghang Hardware Products Factory specializes in manufacturing hardware accessories mechanical bead chain machine, snake chain machine, chain weaving chain machine, Wanzi chain machine, jewelry net machine, ring machine, sub-chain machine, etc. , hardware jewelry chain, hardware jewelry mesh, bead chain, bead chain single bead bead chain machine mold. Snake chain, 4D chain, twist chain, corn chain, round net chain, flat net chain, foxtail chain, necklace, luggage handbag Chain, jewelry chain, hardware accessories Korean chain, bead chain accessories head bead waist buckle, bead buckle, flower basket buckle, Zhudan buckle, D buckle, triangle buckle, key ring, open ring, lobster buckle, dog buckle, hardware craft jewelry Accessories.